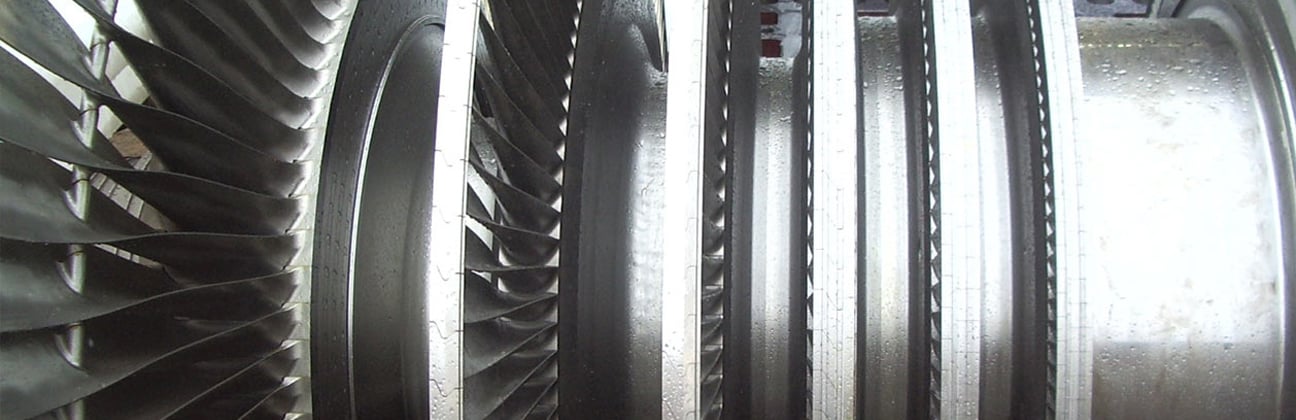

Steam Turbines Services

STEAM TURBINE OUTAGE SUPPORT

Mitsubishi Power meets or exceeds the highest quality standards in the industry while providing competitive, cost-effective support.

Our skilled field technicians provide exceptional comprehensive service, maintenance, and repair for steam turbines across a broad range of manufacturers. They use proven, reliable parts to ensure Mitsubishi Power meets its goal to reduce outage durations and increase profitability for power providers.

STEAM TURBINE FIELD SERVICE

Rapid Response Support

Mitsubishi Power offers rapid response field service solutions that include (but is not limited to) Blade Replacement, Dynamic Rotor Balancing, Generator Inspection & Repair, NDE with Engineering Analysis, Rotor Welding & Machining, Stationary Component Welding & Machining, Technical Advising Services, Turnkey Outage Services, Valve Inspection (including repair and calibration), and Vibration Testing & Analysis.

| Blade Replacement | Rotor Welding & Machining | Turnkey Outage Services |

| Dynamic Rotor Balancing | Stationary Component Welding & Machining | Valve Inspection, Repair & Calibration |

| Generator Inspection & Repair | Technical Field Advisor | Vibration Testing & Analysis |

| NDE with Engineering Analysis |

Our unique 100,000 Hour Life Assessment Inspection examines the effects of aging on your steam turbines. We can determine the current condition of your turbine and provide service and repair recommendations to reduce performance and efficiency losses.

Safety First

Safety is at the forefront of everything we do, and Mitsubishi Power’s safety record is consistently exceptional. Extensive pre-outage planning and dedicated project management teams contribute to our long history of successful outage executions at nuclear and conventional plants.

STEAM TURBINE UPGRADES

Advanced 3D Design

Through extensive, ongoing Research & Design (R & D) efforts Mitsubishi Power developed and continues to refine its 3D blade designs to provide the most efficient and durable blade paths.

Our 40-year collaboration with Westinghouse led to the development of over 400 new steam turbines with enhanced design features, and our thorough analysis of blading and fleet operating issues led to significant improvements, most notably the enhancements to our interlocked Integral Shroud Blades (ISB).

There are more than 1100 Mitsubishi Power units in operation, and we offer a variety of steam path upgrades for these as well as steam turbines designed by other manufacturers.

Improved Reliability & Extended Performance

Our new cylinder, blade ring and seal carrier designs manage thermal distortion to help maintain blade path alignment and create more efficient seals.

Mitsubishi Power uses advanced 3D modeling to ensure thermal growths of new stationary components match the thermal growth of the rotor to maintain tight seal clearances.

Our advanced ISBs provide high damping characteristics to allow a full range of operating loads, even at high backpressure conditions.

Mitsubishi Power’s robust designs and absolute requirement to test all new technologies in-house have resulted in the long-lasting, reliable performance of our replacement components.

Turnkey Installation

Mitsubishi Power’s Turnkey Installation with Startup Support ensures smooth installation of our replacement rotors and stationary components. We provide single-point dedicated project management, from contract signing through final acceptance testing.

STEAM TURBINE PARTS

We supply industry-leading, durable, and reliable steam turbine parts. Our in-kind and upgraded steam path components (Forged Blades, Machined Blades, Active Clearance Control Seals, etc.) can recover the efficiency and performance that’s been lost after years of deterioration.

Mitsubishi Power’s valve subassemblies and upgraded value components enhance reliability and reduce outage durations.

REMOTE MONITORING

Mitsubishi Power experts have the ability to monitor the operating conditions of your steam turbine with the Remote Monitoring and Diagnostics (RMC) center. The team uses state-of-the-art software capable of detecting anomalies with the equipment’s operation, as well as diagnosing performance concerns based on operating data. Data from your site is streamed into the RMC in real-time, allowing Mitsubishi Power technical experts the ability to provide proactive support to keep your unit operating, providing improved Reliability and Availability of your power plant, which makes this system a very dynamic and collaborative diagnostic tool.

In addition to operation support, the RMC also offers engineering analysis, combustion tuning support and digital twin modeling. TOMONI™ technology provides the RMC team an analytic framework to find actionable insights to maximize availability and minimize operational costs. Units supported by the RMC enjoy improved Reliability and Availability as a testimony for the excellent coverage provided.